Enhanced Hygiene Protection on your Wall Linings and Ceiling Tiles with Climate® Powder Antimicrobial Formulations

Climateline® and Ecotile™ plasterboard linings now feature BioCote® antimicrobial technology in their powder-coated surface, offering increased levels of protection against bacteria, mould, and fungi for your projects that need to meet high hygiene standards.

Climate is pleased to announce the latest development in their zero-VOC powder coating technology, with the addition of the BioCote® antimicrobial technology. This ensures greater bacterial and mould resistance for linings where hygiene is crucial including; hospitals, schools, restaurants, food processing plants, laboratories, gyms and more.

Increased resistance against bacterial growth for hygiene critical areas

BioCote® active ingredients disrupt the cellular functions of microorganisms, to prevent their survival on treated surfaces.

By incorporating BioCote® into Climate Surfaces powder coating formulas, it offers peace of mind that Climateline® and Ecotile™ products actively reduce and minimise bacteria and mould — helping to keep surfaces fresher for longer, reducing odours, and making maintenance easier in demanding environments.

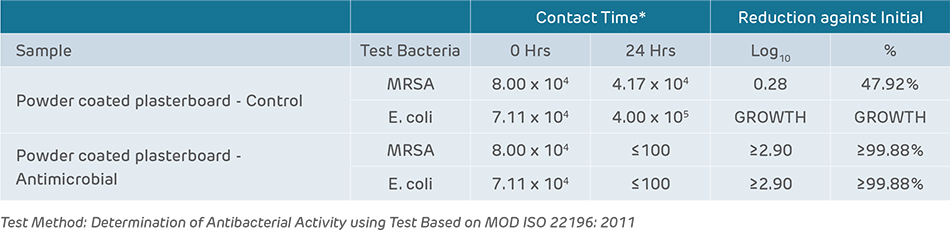

Tested to reduce up to 99% of bacteria in 24 hours

Rigorous testing confirms that BioCote® technology in Climate powder coatings reduces up to 99.9% of bacteria, including Staphylococcus aureus and Escherichia coli within 24 hours.

Long-lasting surface protection from mould, odours and discolouration

In addition to the antimicrobial effect, the BioCote® additive in Climate powder coatings contributes to reduced mould growth, odours and stains that can affect a surface over time — typically caused by bacterial growth. This ensures Climateline® and Ecotile™ retain their performance and visual appeal for longer — even in areas exposed to significant moisture and robust cleaning schedules.

NZ made, Global Greentag certified, Climateline® and Ecotile™ — now with BioCote® are available nationwide from Comfortech Building Performance Solutions.